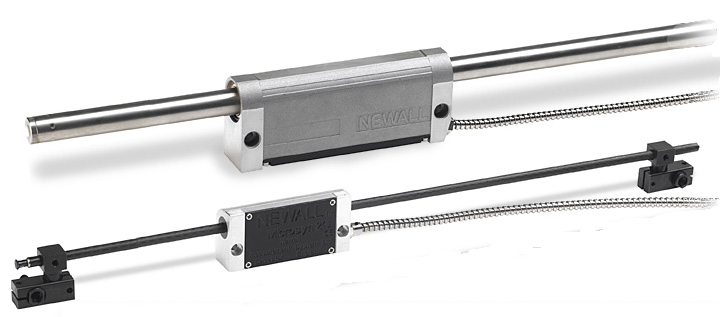

Newall Electronics - Digital Readout (DRO) and Linear Encoders

Newall Electronics is a global specialist of high-quality and high-performance digital readout systems (DRO) and linear feedback encoders, supplying reliable, accurate and dependable products for a wide variety of measuring applications worldwide. Newall's unique inductive encoder technology provides uncompromising accuracy within the harshest and most extreme environmental conditions, specifically in machine tool applications. Newall backs its products with a global team that is dedicated to providing its customers the highest level of technical support and customer service.